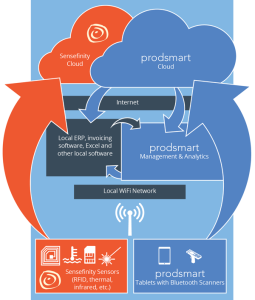

Two Portuguese companies, Prodsmart – that focuses on developing process optimization systems for industrial production – and Sensefinity – that’s specialized in integrating sensors with other systems – just announced a partnership. Their goal is to bring the advantages of the Internet of Things to the factory floor.

From now on, it is possible to see all the factory floor operations in real time, from people’s work to everything that is produced in each machine in every production line.

Everything that can be automated is detected by Sensefinity’s sensors. The data is transmitted instantly to Prodsmart’s technological infrastructure and the information is made available to the production manager so that he knows how the operations are going.

Everything that can be automated is detected by Sensefinity’s sensors. The data is transmitted instantly to Prodsmart’s technological infrastructure and the information is made available to the production manager so that he knows how the operations are going.

As Gonçalo Fortes, CEO of Prodsmart stated,

“In the manufacturing industry, having production information always available and updated can lead to a real revolution in how they make decisions, with significant implications in terms of cost savings and productivity gains. Whether we are talking about connecting people in the same factory or production line, or connecting the sales system to the productive system, there’s an immediate impact in terms of reducing production times, optimization of processes and the reduction or elimination of stocks.”

According to Orlando Remédios, CEO of Sensefinity,

This partnership will allow us to have a solution specifically designed for the manufacturing industry, similar to what we already have for other industries, such as agricultural units or a university campus.

The Internet of Things is growing and expanding. We are looking forward to see the results of this partnership, in real time and detail.